Services

Torklift Central is your trailer hitch installation center and custom fabrication welding experts just 20 minutes south of Seattle, located in Kent.

Torklift Central

253-854-1832

315 Central Ave N

Kent, WA 98032-4595

Torklift Central is where you want to go for all your trailer hitch, fifth wheel, trailer repair, bike rack and welding needs because of our experience. Not only have we been doing this since 1976, we also have a world-wide distributed brand of trailer hitches, truck camper tie downs and an RV step line featured straight from the factories of Lance Campers and Forest River. We offer a Lifetime Workmanship Warranty because we are in this for the long-haul with you as well as a Legendary Lifetime Warranty on all our branded house products.

With all types of hitch installs, bike rack brands, welding services and yep – we even have trailers for sale near you living in Seattle, Tacoma, Bellevue, Renton, Bonney Lake, Sumner, Auburn, Enumclaw – you name it. Sitting centrally in Kent, we are here for you.

Check out our offering below – and if you don’t see it, give us a call – there’s nothing we can’t do for you in the RV industry.

Trailer Hitch Install

Bike Racks and Cargo

Anti-Theft Devices

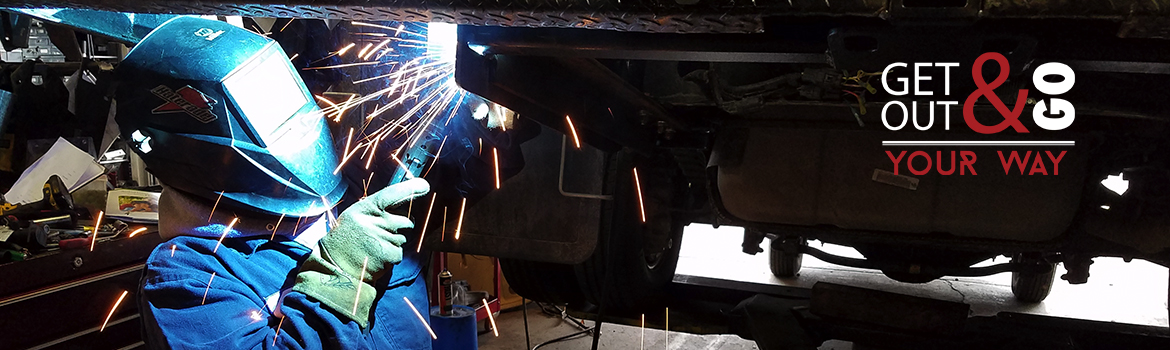

Welding

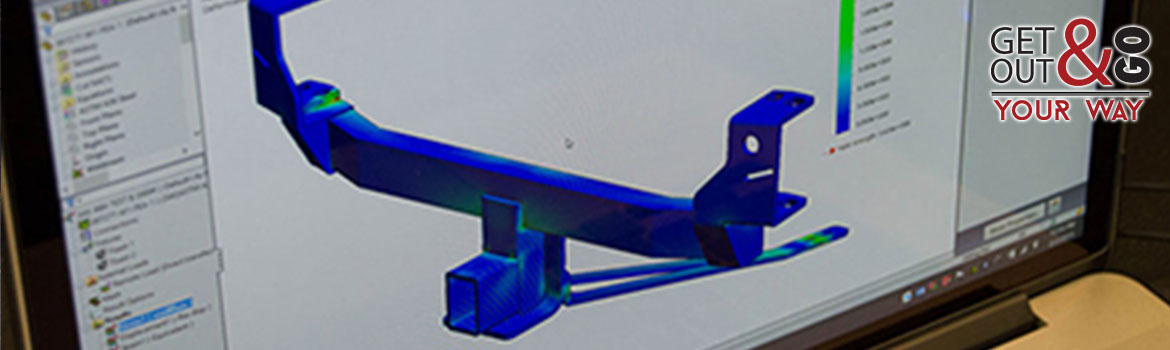

- Custom fabrication

- Custom metal fabrication

- 3D printing

- CNC plasma cutting

- Railings and Decorative Welding

- Church pulpits and crosses

4x4

RV Services

- Electrical wiring

- Truck Campers

- Tow Bars

- Travel Trailers and Fifth Wheels

- Weight Distributing Hitches

- Motorhome Chassis Frame Upgrade

- Motorcycle Carriers

Snow Plows

Trailer Hitch Installation

Trailer Hitch Installation Free Safety Inspection

Free Safety Inspection Welding

Welding Trailer Axle Services

Trailer Axle Services Trailer Suspension Services

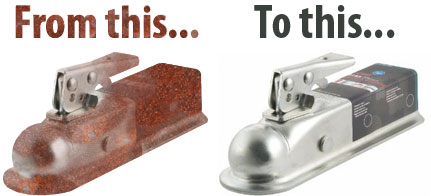

Trailer Suspension Services Trailer Coupler Repair

Trailer Coupler Repair Trailer Brakes and Service

Trailer Brakes and Service Trailer Wiring Services

Trailer Wiring Services Hydraulic Dump Trailer Services

Hydraulic Dump Trailer Services Trailer Decking Repair

Trailer Decking Repair Trailer Wheel Bearing Services

Trailer Wheel Bearing Services Motorhome Chassis Frame Upgrade

Motorhome Chassis Frame Upgrade 3D Printing and Scanning

3D Printing and Scanning Custom Fabrication

Custom Fabrication CNC Plasma Cutting

CNC Plasma Cutting Church Pulpits and Crosses

Church Pulpits and Crosses Vehicle Pick Up & Delivery Service

Vehicle Pick Up & Delivery Service Trailer Repair

Trailer Repair Boat Trailer Repair near me

Boat Trailer Repair near me Car Trailer Repair near me

Car Trailer Repair near me Cargo Trailer Repair and Enclosed Trailer Repair near me

Cargo Trailer Repair and Enclosed Trailer Repair near me Dump Trailer Repair near me

Dump Trailer Repair near me Flatbed Trailer Repair near me

Flatbed Trailer Repair near me Food Truck Repair near me

Food Truck Repair near me Horse Trailer Repair near me

Horse Trailer Repair near me Snowmobile Trailer Repair near me

Snowmobile Trailer Repair near me Utility Trailer Repair near me

Utility Trailer Repair near me Torklift Central – Snow Plow Installation

Torklift Central – Snow Plow Installation