All You Need to Know About Trailer Wheel Bearings

It's finally summer! Time for an adventure!

It’s officially summer! June 20th marked the first day of summer which means it’s time to come out of hibernation and go on some adventures! Before you take your trailer out, make sure your trailer is road ready to prevent trailer wheel bearing failure in the future.

When your trailer sits in storage for prolonged periods, as most trailers do between travel seasons, moisture has the opportunity to get into the wheel bearings and break down your wheel bearing grease. These issues are particularly dangerous for boat trailer wheel bearings that are continually dunked in water where moisture is much more likely to make its way into the wheel bearings.

Warning Signs

Noise is a classic sign of bad or rusted wheel bearings. Here are some typical signs that you may be experiencing trailer wheel bearing failure:

• Snapping, clicking or popping: typically heard when cornering or making sharp turns

• Grinding when the vehicle is in motion: normally heard when turning or when the load is shifting

• Wheel vibration or wobble: indicates the loss of a bearing race or a bearing with extreme mechanical damage

What Your Wheel Bearings Need

In order to do their job, your wheel bearings need plenty of fresh grease with a trailer wheel bearing repack to make sure inner components avoid excessive heat generation that could lead to breakdown. Greasing wheel bearings creates a new seal in order to ensure each part is working properly. The following are some common questions about trailer bearing repack service:

How often do I repack wheel bearings? Torklift Central and all trailer axle manufacturers recommend performing a wheel bearing repack service at a minimum annually, especially around the time you bring it out of storage. Doing this ensures that your wheel bearings are fit for travel before hitting the road.

How do you repack wheel bearings? Repacking trailer wheel bearings is a pretty straightforward process. Some of the steps involve:

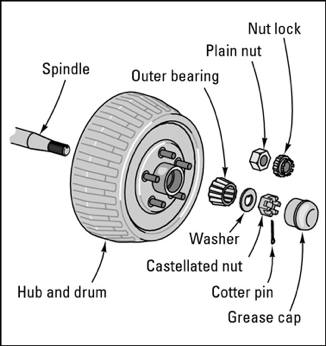

What a wheel bearing setup looks like

•Removing the wheel and the hub at the end of the spindle of your trailer (the bearings are located in the hub)

• Remove the bearings, clean them out, clean out all the old grease

o Replace the bad ones that look suspect

• Pack grease into the bearing as well as the inside of the hub

• Reinstall all the parts back into the hub and onto the spindle

This process should be done for each hub in order to make sure your trailer is up to snuff. Torklift Central can easily repack your trailer wheel bearings starting at $116. Call to schedule an appointment today at 877-343-6933.

How do you remove rusted wheel bearings? At Torklift Central we can also remove rusted wheel bearings. With rusted wheel bearings, the best way to solve this issue is to follow the same steps of repacking your wheel bearings.

Don't get stuck with rusted wheel bearings

If there is a bad or broken wheel bearing you should take your trailer to Torklift Central for trailer repair. Also make sure to schedule a free safety inspection for your trailer. We also check for bearing tension and whether your trailer needs a bearing repack service.

Get Out and Go knowing your trailer is safe for the road and come in for a trailer service today. To schedule your trailer wheel bearing repack service, contact us here:

Torklift Central

315 Central Ave N Kent, WA 98032

[email protected]

877-343-6933

www.torkliftcentral.com

Written by Kerstin Stokes:

Written by Kerstin Stokes:

As a graduate from the College of Idaho with a B.A. in both History and Art, Kerstin has found her passion for writing and marketing. She enjoys looking up tasty recipes for baking and daydreaming about future travels.